TECHNOLOGY

PLASTIC ENGINEERING

- We use knowledge of chemistry, physics, engineering and math to develop plastic parts.

CHEMISTRY ENGINEERING

- Dedicated on compound, ingredient fomulation.

- Comprehensive rubber procedure.

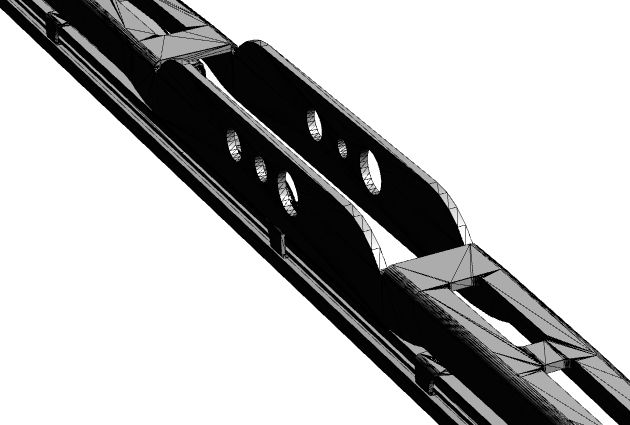

DESIGN

- Structure, function, suitability.

TESTING LAB

- SAE J903C standard.

MATERIAL QUALITY ASSURANCE

- Strict IQC process.

- Non-regrind material.

TOOLING CREATION

- Specialist for creating, trial, adjustment and maintenance.

- Extensively tool creation facilities for Hardware, Plastic, Rubber, Gauge and Packaging Molds.

RUBBER ENGINEERING

- Refined rubber facility with accurate formulation.

- Automation process from raw material to finish parts.

- Quality guaranteed.

RUBBER COMPRESSION MOLDING

- Customized Control System for Efficiency, Stable and Precise.

- OEM Qualification.

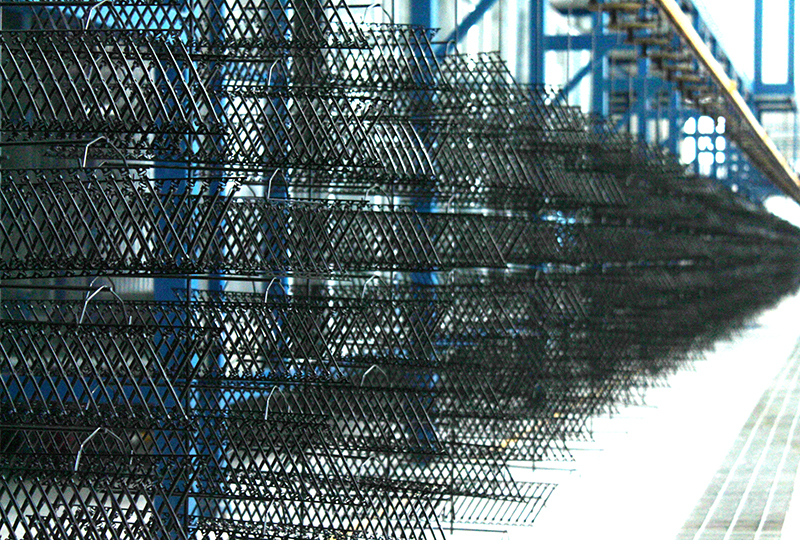

PAINTING

- Automated Powder/ Liquid Coating Line.

- Automated Electro-Deposit(ED) Coating Line.

- Exquisite surface with strong corrosion resistance ability.

QUALITY CONTROL

- IATF 16949 Qualification.

- Internal PPAP & ISIR Control process.

- Strict & Regular Inspection for IQC.

- On site QC Station in every workshops.

- Dock Audit before Shipment.